Blog

Does Composite Decking Warp or Crack in Harsh Weather? A Builder’s Guide to Long-Term Durability

Problem: You’re designing a deck for a coastal home or a mountain cabin. Your client wants a low-maintenance solution, but they’re worried: “Will this deck warp or crack after a few winters or summers?”

Agitation: Warping and cracking are deal-breakers. A distorted deck not only looks unprofessional but also raises safety concerns. Your reputation hinges on delivering materials that withstand extreme heat, cold, and moisture.

Solution: Let’s tackle durability head-on. While composite decking is engineered for resilience, its performance depends on material quality, installation, and environmental factors. Here’s what builders and designers need to know.

Why Does Composite Decking Warp or Crack? Key Factors Explained

Composite decking resists warping better than wood, but no material is invincible. Here’s the science behind structural stress:

1. Temperature Extremes

- Expansion/Contraction: Composite materials expand in heat and contract in cold. Poorly spaced boards can buckle or gap.

- Surface Temperature: Dark-colored decks in direct sun can reach 160°F+ (71°C), accelerating wear on lower-quality products.

2. Moisture Absorption

- Cap Layer Integrity: Uncapped composites absorb moisture, causing swelling and eventual cracking in freeze-thaw cycles.

- Substructure Issues: Trapped moisture beneath the deck (due to poor ventilation) weakens the frame, indirectly stressing boards.

3. Material Quality

- Filler Content: Cheap composites use excess wood flour or recycled plastics, reducing structural stability.

- Manufacturing Defects: Inconsistent mixing or cooling during production creates weak points prone to cracking.

4. Installation Errors

- Inadequate Gaps: Less than 1/8″ spacing between boards can lead to warping under thermal expansion.

- Improper Fastening: Overdriven screws or misaligned hidden clips strain the decking.

How Likely Is Warping or Cracking? Real-World Scenarios

Uncapped vs. Capped Composite Decking:

| Feature | Uncapped Composite | Capped Composite |

|---|---|---|

| Moisture Resistance | Moderate (absorbs 0.5-1% moisture) | High (near 0% absorption) |

| Thermal Stability | Prone to expansion/contraction | Engineered for minimal movement |

| Warranty Coverage | 10-15 years | 25+ years (lifetime options) |

| Cost | 5/sq. ft. | 12/sq. ft. |

Case Studies:

- Coastal Florida Home: Uncapped deck warped 1/4″ after 2 years of humidity and salt spray. Replaced with capped composite; no issues after 5 years.

- Colorado Mountain Cabin: Temperature swings (-20°F to 90°F) caused uncapped boards to crack at fastener points. Capped decking with thermal-gap spacing remained intact.

How to Prevent Warping and Cracking: Pro Tips for Builders

1. Choose High-Quality Capped Composite

- Prioritize brands with polyethylene caps and 60-70% polymer content (vs. 40% in budget options).

- Look for ASTM D7032 certification for weather resistance.

2. Follow Precision Installation Practices

- Spacing: Allow 1/8″–1/4″ gaps between boards (wider in extreme climates).

- Ventilation: Install a 18″+ ground clearance and use airflow-promoting substructures.

- Fasteners: Use stainless steel screws or hidden clips designed for thermal movement.

3. Design for Climate Challenges

- High Humidity: Opt for lighter colors to reduce surface heat and expansion.

- Freeze-Thaw Zones: Ensure proper drainage and slope (1/4″ per foot) to prevent water pooling.

4. Educate Clients on Maintenance

- Annual Inspections: Check for debris blocking gaps or loose fasteners.

- Cleaning: Use a soft-bristle brush to avoid abrasive damage to the cap layer.

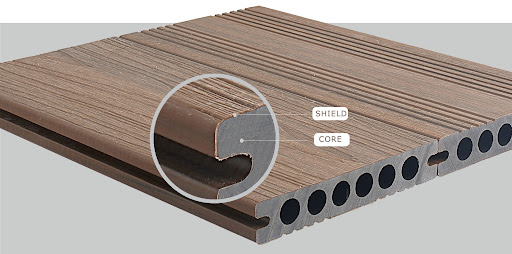

Why Plastory’s Capped Composite Outperforms

- Triple-Layer Cap: A 360° protective shell against moisture, UV rays, and thermal stress.

- Hybrid Polymer Core: 65% recycled HDPE + rice hull fibers for unmatched stability.

- Climate-Specific Engineering: Boards pre-spaced for regional temperature ranges (e.g., 1/4″ gaps in Midwest vs. 3/16″ in Pacific Northwest).

Proven Results:

- Zero warping/cracking reports in -30°F Minnesota winters or 120°F Arizona summers over 8+ years.

FAQ: Answering Builder and Designer Concerns

Q: Can warped composite decking be repaired?

A: Slight warping may settle with seasonal changes. Severe cases require board replacement.

Q: Do composite decks need expansion joints?

A: For runs over 20 feet, add 1/2″ expansion joints to accommodate movement.

Q: How does composite compare to PVC decking?

A: PVC resists moisture better but is prone to sagging under heavy loads. Composite offers superior load-bearing and fire resistance.

Q: Will heavy snow load cause cracking?

A: High-quality capped composites support 500+ lbs/sq. ft.—well above typical snow loads.