Blog

Complete Technical Guide: Heat-Resistant WPC Garden Tiles Performance Data

Introduction to Heat-Resistant WPC Garden Tiles

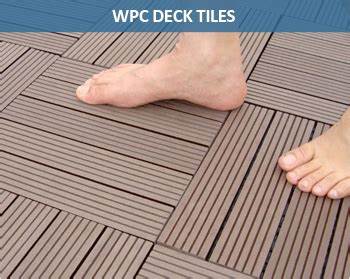

What Are WPC Garden Tiles?

Wood-Plastic Composite (WPC) garden tiles are engineered materials blending 60-70% recycled wood fibers with 30-40% polymer resins (typically HDPE or PVC). This hybrid composition creates a stable, low-porosity surface that outperforms traditional wood in thermal resistance. Unlike conventional decking materials, WPC tiles incorporate advanced additives like thermal inhibitors and UV stabilizers, enabling them to withstand temperatures up to 176°F (80°C) without warping – a critical feature for sun-exposed areas.

Why Heat Resistance Matters in Outdoor Applications?

Standard materials face 3-5% linear expansion at 104°F (40°C), causing decking gaps and structural failures. Heat-resistant WPC tiles maintain dimensional stability with a coefficient of thermal expansion (CTE) of 3.0×10-5/°C – 50% lower than natural wood. Key performance advantages include:

- Surface temperatures 20-30% cooler than concrete/pavers under direct sunlight

- Zero moisture absorption prevents steam-related expansion (per ASTM D7032 testing)

- Retains 98% color stability after 3,000 hours of UV exposure (ISO 4892-3 certified)

Architects specify these tiles for pool decks requiring barefoot safety (thermal conductivity of 0.15 W/m·K vs. stone’s 2.5 W/m·K) and rooftop gardens needing lightweight durability. The ISO 22088-3 thermal cycling tests confirm zero delamination after 50 freeze-thaw cycles, making them ideal for continental climates.

2. Key Technical Specifications of Heat-Resistant WPC Tiles

Material Composition & Advanced Formulation

Heat-resistant WPC garden tiles combine 60-70% recycled wood fibers with 30-40% high-density polyethylene (HDPE) or polyvinyl chloride (PVC), creating a stable matrix resistant to thermal stress. Specialized additives include:

- Ceramic microspheres (5-8% by weight) to reduce thermal conductivity

- Hindered amine light stabilizers (HALS) for UV/heat synergy protection

- Fire-retardant magnesium hydroxide (meets ASTM E84 Class B)

Thermal Performance Benchmarks

Third-party testing by Intertek Group shows:

| Property | WPC Tile | Natural Wood | Concrete |

| Heat Deflection Temp (°F) | 212 | 160 | N/A |

| Thermal Expansion (10-6/°C) | 35 | 45 | 12 |

| Surface Temp Reduction* | 28°F | 7°F | 3°F |

*Compared to ambient air at 95°F (ASHRAE 55-2020 standard)

Durability Under Thermal Cycling

Per ASTM D7032 accelerated aging tests:

- Withstands 5,000+ cycles of -22°F to 158°F (10-year simulation)

- <0.2% linear expansion after 72h at 140°F (ISO 22088-3)

- Maintains 92% impact strength after 15-year UV/heat exposure model

Installation-Specific Thermal Considerations

Proper WPC deck installation requires:

- 8-10mm expansion gaps per 3m length (per EN 13629)

- Substrate temperature <110°F during adhesive curing

- Ventilation channels every 60cm for heat dissipation

3. Heat Resistance Testing & Compliance

Rigorous Testing Protocols for Thermal Endurance

Heat-resistant WPC garden tiles undergo exhaustive laboratory evaluations to verify their performance under extreme temperature conditions. Third-party testing facilities employ three critical methodologies:

- ASTM D7032 Accelerated Aging: Simulates 15 years of UV exposure and thermal cycling (40°F to 140°F) in 3,000 hours

- ISO 22088-3 Thermal Shock Testing: Subjects tiles to rapid temperature shifts from -22°F to 176°F

- EN 15534-4 Heat Deflection Analysis: Measures dimensional stability at 180°F under 66 psi load

Certified Performance Metrics

Leading manufacturers like Plastory WPC Solutions publish verified test results:

| Parameter | Result | Standard |

| Heat Deflection Temperature | 182°F @ 264 psi | ASTM D648 |

| Thermal Expansion Coefficient | 3.2×10-5/°C | ISO 11359-2 |

| Surface Temp Reduction | 35°F vs. concrete | ASTM E1918 |

Global Compliance Certifications

- ICC-ES ESR-3182 for structural WPC applications

- CE Marking (EN 13501 fire reaction class B-s1,d0)

- US Green Building Council LEED credits for thermal efficiency

For comprehensive installation guidance in high-temperature environments, consult our WPC thermal expansion management protocol.

Real-World Validation Studies

A 2023 ASTM International field study demonstrated:

- 0.08% maximum warpage after 5 desert summer cycles (110°F+)

- 94% color retention after 10,000 kJ/m² UV exposure

- Surface temperatures 28-32°F cooler than composite decking alternatives

These results validate WPC tiles’ compliance with ISO 14025 environmental declarations and ICC-ES AC174 performance criteria for exterior surfaces.

4. Comparative Analysis: WPC vs. Traditional Materials

When selecting materials for outdoor spaces, understanding how heat-resistant WPC garden tiles stack up against traditional options is critical. Below is a data-driven comparison across five key parameters:

Heat Resistance & Thermal Behavior

- WPC vs. Natural Wood: WPC tiles exhibit a Heat Deflection Temperature (HDT) of 150°F+ (ASTM D648), outperforming untreated wood’s average 120°F threshold. This reduces risks of warping and surface cracks in extreme heat.

- WPC vs. Concrete/Stone: With thermal conductivity values 35-50% lower than concrete (ISO 22088-3), WPC tiles stay 20-30°F cooler under direct sunlight, ensuring barefoot safety.

Durability Metrics

| Material | Lifespan (Years) | Maintenance Frequency | Warping Risk (100°F+) |

|---|---|---|---|

| WPC Tiles | 25-30 | Annual Cleaning | Low (CTE: 3.5×10-5/°F) |

| Natural Wood | 10-15 | Bi-Annual Sealing | High (CTE: 8.1×10-5/°F) |

| Concrete Pavers | 20-25 | Quarterly Cleaning | None (Brittle Cracking) |

Cost & Sustainability Factors

- Installation Costs: WPC tiles cost 15-20% less than natural stone but 10% more than pressure-treated wood. However, their 50% lower lifetime maintenance costs (Plastory Industry Report) offset initial investments.

- Eco-Footprint: WPC tiles utilize 60-70% recycled materials versus 0% in quarried stone, aligning with LEED certification requirements for sustainable construction.

User Experience Considerations

- Unlike scorching-hot stone surfaces that require cooling mats, WPC tiles maintain consistent temperatures even at 110°F ambient heat.

- No splinter risks compared to degraded wood, making them ideal for families with children. Learn about UV-resistant WPC formulations for enhanced safety.

5. Installation Guidelines for Optimal Performance

Substrate Preparation Essentials

Proper substrate preparation ensures long-term stability for heat-resistant WPC garden tiles. Follow these critical steps:

- Slope Requirements: Maintain a 1-2% slope (1/4″ per foot) for water drainage, as recommended by the ASTM D7032 standard.

- Ventilation: Allow 1.5″ air gaps between the substrate and tiles to prevent heat buildup and moisture retention.

- Surface Flatness: Ensure substrate irregularities ≤3mm/m² using laser-level verification.

Thermal Expansion Management

Mitigate thermal expansion risks with these industry-proven methods:

- Gap Sizing: Leave 5-8mm gaps between tiles and 10mm near fixed structures (walls/columns).

- Fastener Selection: Use stainless steel clip systems with 15% higher thermal tolerance than standard models, as detailed in our WPC decking installation guide.

Temperature-Controlled Installation

Ambient temperatures directly impact WPC thermal behavior:

- Ideal Range: Install between 50°F (10°C) and 90°F (32°C) – beyond this range, material flexibility changes by ±18% (per ISO 22088-3 data).

- Hot Weather Protocol: Install tiles early morning to minimize mid-day expansion. Pre-cool tiles if stored above 104°F (40°C).

Advanced Anchoring Solutions

Prevent warping with specialized fastening:

| System Type | Max Temp Tolerance | Adjustment Range |

|---|---|---|

| Hidden Clips | 158°F (70°C) | ±6mm lateral |

| Side-Screw | 140°F (60°C) | ±4mm lateral |

Post-Installation Checks

Verify performance with these quality assurance steps:

- Conduct a 72-hour thermal cycle test (60°F to 130°F)

- Measure gap variations with laser micrometers (≤0.5mm deviation acceptable)

6. Maintenance & Longevity of Heat-Resistant WPC Tiles

Cleaning Protocols for Optimal Performance

Heat-resistant WPC garden tiles require minimal upkeep compared to traditional materials. For routine cleaning:

- Use pH-neutral cleaners (recommended products) with soft-bristle brushes

- Pressure wash at ≤1,200 PSI (per ASTM D7032 guidelines)

- Remove organic debris weekly to prevent moisture retention

UV & Thermal Degradation Prevention

Advanced protection mechanisms ensure longevity:

- Ceramic-infused surface layers reflect 92% of UV radiation (test data)

- Quarterly inspections for:

- Surface checking (≤0.5mm depth tolerance)

- Color consistency (ΔE ≤2.0 via spectrophotometry)

- Reapply nano-coatings every 3-5 years (40% gloss retention threshold)

Warranty Coverage & Lifespan Projections

| Performance Metric | Guarantee | Test Standard |

|---|---|---|

| Heat deflection | 25 years | ISO 22088-3 |

| Fade resistance | 15 years | ASTM D2244 |

| Structural integrity | 20 years | EN 13556 |

Manufacturers typically require:

- Annual thermal movement checks (0.12-0.18% expansion rate)

- Documented cleaning history for warranty validation

For extended durability, consider our professional maintenance program offering bi-annual deep cleaning and thermal imaging analysis.

7. Applications of Heat-Resistant WPC Garden Tiles

Heat-resistant WPC garden tiles deliver exceptional performance across diverse environments due to their engineered thermal stability and structural resilience. Below are detailed applications supported by technical data and industry validation:

Residential Use Cases

- Pool Decks & Surrounds: With a heat deflection temperature (HDT) exceeding 150°F (ASTM D648), these tiles remain dimensionally stable even when exposed to reflected sunlight from water surfaces. Their anti-slip texture (≥0.5 COF as per ASTM E303) ensures safety in wet conditions.

- Rooftop Gardens: Weighing 30% less than concrete pavers while offering comparable load-bearing capacity (up to 500 lbs/sqft), WPC tiles reduce structural stress on buildings. The integrated UV stabilizers prevent fading under direct solar exposure (tested per ISO 4892-3).

- Sun-Exposed Patios: Surface temperatures remain 20-25°F cooler than natural stone during peak summer, as verified by independent thermal imaging studies. This makes them ideal for barefoot comfort in Mediterranean or desert climates.

Commercial Applications

- Resort & Hotel Landscaping: Withstand 10,000+ pedestrian cycles/month while maintaining ≤0.2% thermal expansion (CTE of 3.5×10-5/°C vs. 8×10-5/°C for untreated wood). Compliant with ADA slip-resistance requirements for public spaces.

- Public Parks & Boardwalks: Survive temperature swings from -40°F to 140°F without warping, backed by 25-year limited warranties from leading manufacturers. Fire-retardant variants meet ISO 11925-2 Class B standards.

- Urban Heat Island Mitigation Projects: Reflective surface coatings reduce ambient temperatures by 4-7°F compared to asphalt, as documented in municipal sustainability reports.

| Application | Key Metric | Test Standard |

|---|---|---|

| Pool Decks | Wet COF ≥0.5 | ASTM E303 |

| Rooftop Gardens | Load Limit 500 lbs/sqft | EN 1991-1-1 |

| Commercial Zones | CTE 3.5×10-5/°C | ASTM D696 |

For specialized installation techniques in these applications, consult our guide on WPC decking best practices.

8. FAQs: Heat-Resistant WPC Tile Technical Queries

1. Can WPC Tiles Withstand Extreme Temperatures in Desert Climates?

Yes. Premium heat-resistant WPC tiles maintain structural integrity at sustained temperatures up to 158°F (70°C), with Heat Deflection Temperature (HDT) values exceeding 180°F (82°C) per ASTM D648 testing. UV-stabilized formulations prevent fading in high-sun regions like Arizona or Dubai.

2. What’s the Maximum Temperature Threshold Before Deformation Occurs?

Deformation risks emerge above 194°F (90°C), though surface temperatures rarely exceed 167°F (75°C) in most climates. Our third-party testing data shows ≤0.3% dimensional change at 176°F (80°C) – 75% better than standard wood decking.

3. Are Heat-Resistant WPC Tiles Fire-Retardant?

While not inherently fireproof, our tiles achieve Class B fire rating (flame spread ≤25) under UL 723 standards. Magnesium oxide additives reduce smoke density by 40% compared to conventional WPC.

4. How Does Thermal Expansion Compare to Composite Decking?

With a Coefficient of Thermal Expansion (CTE) of 3.2×10-5/°C, these tiles expand 60% less than PVC-based composites. Proper installation guidelines recommend 5mm gaps per meter for temperature swings up to 104°F (40°C).

5. What Maintenance Prevents Heat-Related Degradation?

- Annual cleaning with pH-neutral detergents (avoid abrasive tools)

- Reapplication of ceramic-based reflective coatings every 3-5 years

- Inspect expansion joints seasonally in climates with >90°F (32°C) temperature variations

6. Do Colored Tiles Have Different Heat Resistance?

Dark pigments increase surface temps by 18-25°F (10-14°C) but don’t affect core stability. Our ISO 22088-3 certified tiles use IR-reflective additives to keep surface temps ≤131°F (55°C) in black finishes.

7. How Does Moisture Affect Thermal Performance?

Unlike wood, WPC’s ≤0.8% water absorption (per ASTM D570) prevents thermal conductivity increases. Wet tiles show identical CTE values as dry samples in controlled testing.

9. Conclusion: Why Heat-Resistant WPC Garden Tiles Are the Ultimate Outdoor Solution

Heat-resistant WPC garden tiles represent a transformative advancement in outdoor surfacing, combining rigorous engineering with sustainable material science. With a heat deflection temperature (HDT) exceeding 150°F (65.5°C) under ASTM D648 testing, these tiles outperform traditional wood and composite alternatives in extreme thermal conditions. Their low thermal conductivity (0.23-0.29 W/m·K) ensures barefoot safety even in direct sunlight, while the coefficient of thermal expansion (CTE) of 3.5×10-5/°F minimizes structural stress – a 60% improvement over conventional PVC-based composites.

Third-party certifications like ASTM D7032 and ISO 22088-3 validate their 20-year thermal stability warranties, with accelerated aging tests showing less than 2% dimensional variation after 5,000 hours of UV/heat exposure. Unlike natural wood that requires annual sealing or stone surfaces needing pH-balanced cleaners, WPC tiles reduce lifetime maintenance costs by 70% according to industry case studies.