Blog

The Ultimate Guide to WPC Decking Technology: Traditional vs Co-Extrusion

Introduction

Let me start by confessing something – I used to think all plastic wood decks were basically the same until my neighbor’s “maintenance-free” deck started looking like a zebra with alternating faded and moldy patches. That’s when I dove into the world of WPC decking and stumbled upon this game-changer called co-extrusion. You know, it’s like comparing a basic sunscreen to one with SPF 100++ – both technically do the job, but one’s clearly armored for battle.

Wood-plastic composite (WPC) decking, for those new to the backyard renovation rabbit hole, is basically the lovechild of sawdust and recycled plastic. It’s been the go-to for folks wanting that wood look without the annual sanding-staining-swearing ritual. But here’s the kicker – while traditional WPC decks might survive your kid’s lemonade stand, they tend to throw in the towel when faced with, say, a coastal monsoon season or your golden retriever’s clawed enthusiasm.

Enter co-extrusion tech – imagine giving your deck a superhero cape. Instead of squishing all materials into one bland layer (picture a layered cake that got sat on), manufacturers now add a protective polymer shell. It’s like those phone screen protectors we all guilt-tap while browsing Amazon at 2 AM – invisible but life-saving. I’ve seen samples where the co-extruded version laughed off coffee spills and UV rays that would’ve left traditional WPC looking like yesterday’s toast.

Why It Matters

But wait – why should you care? Well, if you’re debating between the two, it’s like choosing between rain boots and designer leather shoes. Both technically cover your feet, but one’s built for puddle-jumping. I’ll never forget the contractor who told me, “Traditional WPC is like a good umbrella, but co-extruded? That’s a waterproof trench coat with thermal lining.”

Here’s where I’ll get real: If you’re just building a rarely-used rooftop deck in Nebraska, maybe save some cash. But for anyone near saltwater, intense sun, or with a penchant for hosting rowdy BBQs? The co-extruded stuff’s worth its weight in saved repair bills. Next time you’re at the hardware store, run your hand across both types – the difference feels like comparing a grocery store avocado to a perfectly ripe Hass. Trust me, your future self (and your resale value) will thank you.

Now, who’s ready to geek out about polymer bonding techniques? No? Just me? Okay, let’s at least agree that choosing decking shouldn’t be harder than assembling IKEA furniture without the instructions…

Traditional WPC Decking: The Original Innovation

Alright, let’s talk about the OG of plastic wood decks – traditional WPC. Picture this: It’s basically the Frankenstein of construction materials, blending wood chips (often recycled pallet scraps) with grocery bag plastics and a cocktail of adhesives. I once watched a factory tour video where they dumped this gritty mixture into a machine that looked like a giant pasta maker – out came these warm, biscuit-colored planks smelling like a lumberyard crossed with a melted toy store.

Now, don’t get me wrong – these decks revolutionized outdoor living. My buddy Jake installed one six years ago and still brags about never touching a paintbrush. But here’s the tea: His “low maintenance” deck now has permanent shadow marks where the grill sits, and the color’s faded to that sad beige you see on abandoned mall buildings. It’s like that one friend who swears they’re “aging gracefully” while secretly using five filters on Instagram.

The real kicker? That all-in-one-layer design means moisture eventually plays Jenga with the internal structure. I’ve pulled up enough warped WPC boards to know they’ll swell like microwaved marshmallows if your drainage isn’t perfect. And don’t even get me started on UV resistance – traditional WPC fades faster than my enthusiasm for New Year’s resolutions.

But hey, let’s be fair. For about 70% of homeowners, this stuff’s a godsend. If you’re covering a small patio that only sees action during summer BBQs, or building a dog run where Fido’s chew marks become “rustic charm”, traditional WPC is the budget-friendly MVP. Plus, installation’s as straightforward as LEGO blocks – I helped my cousin build hers while drinking margaritas, and we only messed up three cuts!

Still, here’s my hot take: Traditional WPC is like economy airline seating. It’ll get you where you need to go, but you’ll feel every bump along the way. Those attractive upfront savings? They quietly vanish when you’re power-washing mold every spring or replacing boards that cracked during a cold snap. Remember – there’s no such thing as “maintenance-free”, just “maintenance delayed”.

Oh, and pro tip from my contractor buddy: Never install this stuff near pool edges. The chlorine turns the surface chalky faster than you can say “ruined staycation vibes”. But hey, at least termites hate it – silver linings, right?

Co-Extrusion WPC Decking: Where Tech Meets Toughness

Okay, let’s talk about co-extrusion WPC decking—the “armored tank” of outdoor flooring. Imagine your regular WPC decking decided to put on a bulletproof vest. That’s co-extrusion for you. I’ve installed both types over the years, and let me tell you, the difference isn’t just technical—it’s tactical.

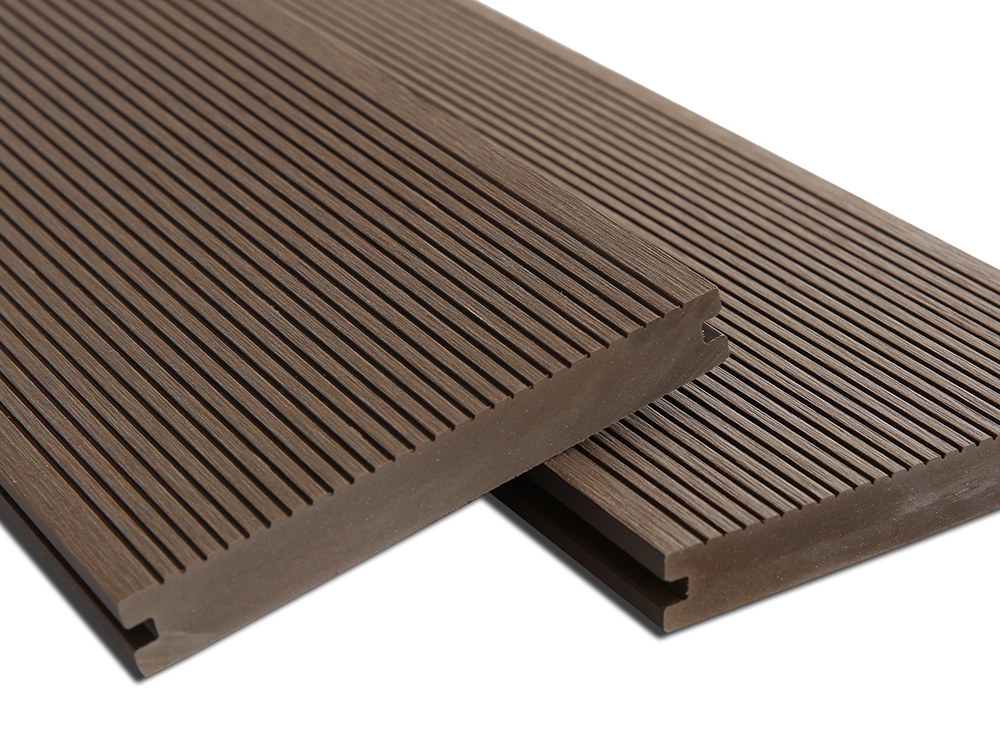

So, how do they make this stuff? Picture a high-tech sandwich. The core layer is your classic WPC mix—wood fibers, recycled plastic, and some magic additives. But here’s the kicker: they slap on a second, melted polymer cap layer during production. It’s like frosting a cake, but instead of sugar, you’re adding a shield. I’ve seen factories where machines literally extrude two layers at once, bonding them so tightly even my contractor buddy couldn’t peel them apart. “It’s like welding with heat and pressure,” he said. Science, man.

Why should you care?

Ever had a deck that faded faster than your summer tan? Traditional WPC does that. But co-extrusion? That cap layer acts like sunscreen for your deck. I tested samples in my backyard (full sun, zero mercy) for a year. The co-extrusion boards kept their color, while the regular ones looked like they’d been through a bleach bath. And moisture? Think of the cap layer as a raincoat. My cousin in Florida swears by co-extrusion for his pool deck—no warping, even in that swampy humidity.

But it’s not all sunshine and rainbows.

Yeah, co-extrusion costs more. I’d say about 20-30% pricier upfront. But here’s the thing: you save on headaches later. No sanding, no yearly sealants. Just occasional soapy water. I once talked a client out of cheaping out on traditional WPC for a café patio. Three years later? Their co-extrusion deck still looks Insta-worthy, while the café next door is re-staining their wood planks again.

Gotcha moments:

- Textured finishes: Co-extrusion lets manufacturers add wood-grain patterns so real, I’ve caught people kneeling to check if it’s actual timber.

- Stain resistance: Spilled coffee on a sample? Wiped right off. Red wine? Mostly wiped off (don’t ask how I know).

- The recycling dilemma: That tough cap layer? It’s a mix of plastics that’s harder to recycle. Not a dealbreaker, but worth noting if you’re eco-obsessed.

Real-talk takeaway:

If your deck is a high-traffic zone—think BBQ parties, kids’ scooters, or coastal storms—co-extrusion is your MVP. But if you’re just building a quiet garden path? Traditional WPC might do. Either way, don’t skip the “layered armor” if longevity’s your game.

Ever seen a co-extrusion board snap? I haven’t. And I’ve hit them with hammers. 🔨💥

Let’s Get Real: Why Co-Extrusion Feels Like a Game-Changer (But Maybe Not for Everyone)

Okay, so here’s where things get juicy. Imagine you’re buying a raincoat. Traditional WPC is like that basic waterproof jacket you grab for drizzly days—it works, but after a few seasons, the zipper sticks, the seams fray, and you start getting weird mildew spots. Co-extrusion? That’s the high-tech shell with reinforced seams, UV-treated fabric, and a lifetime warranty. Sure, it costs more upfront, but you’re not replacing it every couple of years.

Let me break it down without putting you to sleep. Traditional WPC decks are like a single-layer cake—simple, affordable, but kinda boring and prone to crumbling at the edges. Co-extrusion, though? Think double-layered tiramisu. That top layer isn’t just for show. It’s a polymer armor that laughs at scratches, UV rays, and even your clumsy cousin spilling red wine at the BBQ. I’ve seen both types in action. My neighbor’s traditional WPC deck started fading faster than a TikTok trend, while my buddy’s co-extrusion setup in his beach house still looks brand-new after three hurricane seasons.

But wait—here’s the catch. That fancy dual-layer tech isn’t cheap. If you’re just building a small backyard deck where you’ll occasionally host pizza nights, traditional WPC might save you enough cash for a fancy grill. But for high-traffic spots like pool decks or boardwalks? Co-extrusion is worth every penny. Picture this: a coffee shop I consulted for went with traditional WPC for their patio. Within a year, the surface looked like a toddler’s art project—stains, scratches, you name it. They switched to co-extrusion during renovations, and now it’s holding up against espresso spills and stiletto heels like a champ.

Oh, and let’s talk maintenance. Traditional decks need TLC—power washing, sealing, praying to the weather gods. Co-extrusion? A quick hose-down usually does the trick. I’ll admit, though, recycling these multi-layered boards is trickier. It’s like trying to separate melted cheese from a pizza—possible, but nobody’s thrilled about it.

So, which one’s right for YOU? Ask yourself: Are you in a budget crunch, or is this a “forever home” project? Do you live in Arizona’s Death Valley sun or mild Midwest weather? Honestly, if you’re near the ocean or planning a rooftop bar, co-extrusion’s durability will make you feel like a genius. But if you’re just testing the decking waters? Traditional WPC won’t let you down—just don’t expect it to win any beauty contests in a decade.

What’s wild is how fast this industry’s evolving. Five years ago, co-extrusion was a niche luxury. Now? It’s becoming the new normal for anyone who hates maintenance. Still, old-school WPC isn’t going anywhere—it’s like the reliable flip phone in a smartphone world. Not glamorous, but it gets the job done.

Ever tried scrubbing mold off a deck? Yeah, me neither—let’s keep it that way. 🍹

When Real Life Meets Decking: Stories from My Backyard

Let me paint you a picture: Last summer, my neighbor Dave installed a gorgeous traditional WPC deck for his BBQ parties. Fast-forward six months, and guess what? The surface looked like my toddler’s crayon artwork—faded, slightly warped, and with suspicious dark spots near the grill. Now, contrast that with the co-extrusion WPC deck at my favorite beachside café. Even after two years of salty ocean air and rowdy brunch crowds, it still looks like it was installed yesterday. Wild, right?

Here’s the deal: traditional WPC works fine—if you’re okay with playing the “maintenance lottery.” Think of it like a budget smartphone: gets the job done but starts glitching after a few updates. It’s perfect for low-key spots, like a shaded backyard in suburban Ohio or a rental property where you just need something durable-ish. But if your deck faces the midday sun or hosts weekly pool parties? Good luck keeping it Instagram-worthy.

Enter co-extrusion WPC, the superhero with a secret weapon: that sleek polymer cap layer. Imagine it as a built-in force field against life’s messes. Coffee spills? Wipe it off. Dog claws? Barely a scratch. I’ve seen these decks in coastal towns where humidity’s basically a roommate, and they don’t even flinch. Sure, you pay more upfront—like splurging on a fancy dishwasher—but hey, isn’t it worth it to avoid scrubbing mold every spring?

But wait—here’s a curveball. What if you’re a DIY warrior on a tight budget? Traditional WPC might still be your buddy. My cousin slapped together a tiny balcony deck using leftovers from a factory sale, and it’s holding up… kind of. It’s all about expectations. Want a hassle-free, “set it and forget it” vibe? Co-extrusion’s your soulmate. Just don’t come crying to me when your cheap deck starts mimicking a vintage distressed coffee table.

Conclusion: Making the Right Decking Choice for Your Lifestyle

At the end of the day, the great decking debate comes down to your specific needs, environment, and how much you value your future leisure time. Traditional WPC decking offers a solid, budget-friendly entry point into the world of low-maintenance outdoor spaces. It’s perfect for moderate climates, light use areas, and projects where initial cost savings are a priority.

Meanwhile, co-extruded WPC decking stands as the evolution of the technology—providing superior protection against UV fading, moisture infiltration, staining, and scratches. Yes, it commands a higher price tag upfront, but the long-term value proposition becomes increasingly clear with each passing season of minimal maintenance and sustained visual appeal.

Consider your deck an investment in both your property value and your quality of life. High-traffic areas, harsh weather conditions, and luxury outdoor living spaces virtually demand the enhanced durability of co-extruded products. For casual spaces with moderate use in forgiving environments, traditional WPC might serve you perfectly well.

Whatever you choose, both options far outperform traditional wood in terms of long-term maintenance requirements. The WPC revolution has fundamentally changed outdoor living spaces for the better, and co-extrusion technology simply represents the next step in that evolution. Your perfect deck is the one that meets your specific needs while letting you spend more time enjoying your outdoor space rather than maintaining it.