Showing all 4 results

PW-140Y25 – Hollow Traditional WPC Decking

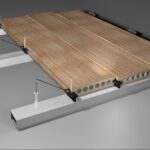

The PW-140Y25 is a traditional hollow WPC decking with a round hole design, offering a perfect balance of strength and reduced weight. Affordable and budget-friendly. Available with grooves on one or both sides, it provides enhanced slip resistance and natural wood aesthetics, making it ideal for terraces, garden paths, and commercial outdoor areas.

PWC-145Y22 – Hollow Co-extruded WPC Decking

PWC-145Y22 is a hollow co-extruded WPC decking by Plastory, designed to offer an ideal balance between weight and durability, while remaining affordable. With a profile width of 145mm and thickness of 22.5mm, this decking is ideal for residential projects and budget-friendly outdoor spaces. Its hollow core design reduces weight, while the co-extruded protective layer provides excellent resistance to UV rays, moisture, and wear.

PWC-90F20 – Hollow Co-extruded WPC Fence

The PWC-90F20 is a hollow co-extruded WPC fence panel designed for a semi-closed effect, combining privacy with ventilation. Its lightweight design and durable co-extrusion technology make it perfect for residential and commercial fencing projects. Available in various colors, it’s a stylish and eco-friendly choice for modern outdoor spaces.

PWD-140Y23 – Hollow 3D Embossed WPC Decking

The PW-140Y25 is a traditional hollow WPC decking with a round hole design, offering a perfect balance of strength and reduced weight. Available with grooves on one or both sides, it provides enhanced slip resistance and natural wood aesthetics, making it ideal for terraces, garden paths, and commercial outdoor areas.

Hollow composite decking is a lightweight, eco-friendly alternative to traditional wood or solid composite boards, available in three main types: traditional hollow decking (budget-friendly with recycled wood/plastic blends), co-extruded hollow decking (UV-resistant surface for high-traffic or coastal areas), and specialty options (anti-slip, fire-rated, or capped designs for pools/commercial use). Ideal for DIY projects, elevated decks, and humid climates, it combines durability (300–400 lbs/sq.ft load capacity), low maintenance (no sealing required), and sustainability (50–80% recycled materials), with costs ranging from $3.50–$8.50/sq.ft depending on type and certifications (FSC/GREENGUARD).

Hollow Composite Decking Vs Solid Composite Decking

| Feature | Hollow Composite Decking | Solid Composite Decking |

|---|---|---|

| Core Structure | Hollow channels (40-60% air pockets) | Fully dense composite material |

| Weight | 1.8-2.5 kg/m² | 3.2-4.1 kg/m² |

| Load Capacity | 250-300 kg/m² (residential use) | 450-600 kg/m² (commercial/heavy-duty) |

| Thermal Expansion | 1.2-1.8% (prone to warping in extreme temps) | 0.5-0.9% (stable in -30°C to 60°C) |

| Noise Dampening | Echo effect underfoot (65-70 dB impact noise) | Superior sound absorption (55-60 dB) |

| Moisture Resistance | Risk of water pooling in cavities | No internal voids (prevents mold growth) |

| Installation Complexity | Requires precise joist spacing (300-350mm) | Tolerates wider joist spacing (400-450mm) |

| Cost (Material Only) | 2.8−2.8-2.8−4.0/sq.ft | 5.5−5.5-5.5−7.2/sq.ft |

| Lifespan | 15-20 years (with maintenance) | 25-30+ years (low maintenance) |

| Fire Rating | Class C (ASTM E84) | Class B (ASTM E84) |

| Eco-Footprint | 30% less raw material used | Higher material use but recyclable core |

| Best Applications | Residential balconies, walkways | Pool decks, rooftop terraces, boardwalks |

Practical Applications of Hollow Composite Decking

Our hollow composite decking product is the perfect solution for any location in need of flooring.

Hollow Composite Decking for Balcony

Hollow Composite Decking for Corridor

Hollow Composite Decking for Garden

Decking for Home Swimming Pool

Hollow Decking for Winnebago

Hollow Composite Decking for Outdoor

Why Choose Us

Are looking for high-quality and cost-effective WPC decking? our products maybe the best choice for hollow composite decking

Mature and great supply chain system

With China's biggest composite production base and full supply chain support, we deliver fast customization of materials while maintaining cost efficiency. Our complete industrial setup allows flexible WPC manufacturing tailored to your project needs.

More Tech accumulation and R&D

With more than 12 years of material engineering expertise, we dedicate not less than 6% of annual revenue to R&D. Our in-house lab develops 5-8 new composite formulas yearly, adapting technologies to meet evolving industry specifications.

Efficient customer service team

Our CS team operates on 2-hour response SLA with ERP-tracked workflows. From project scoping on Monday to Friday FOB shipments, we maintain 97% on-time delivery via Milestone Mapping system, backed by 48-month extended support including root-cause analysis reports.

Strict and Traceable quality control

Our production lines conduct 27 inspections per batch using XRF analyzers and thickness gauges. Certified to ISO 9001:2015 standards, we've maintained <0.3% defect rates since 2020 by implementing automotive-grade quality protocols.

Free and diverse samples to choose

If you don't know how to choose a product, we can send you free samples by mail. Shoot us your project specs – we'll fire back a custom sample kit with 30+ textures/colors, zero cost. So, No need to hesitate to contact us

Instant and professional quotation

Just tell us your demand or idea, we will recommend the best solution include WPC type, specs, and order size for you - our team cracks out a rock-bottom price and tightest delivery schedule in 30 mins flat. No more spreadsheet ping-pong for days.

Tell Us Your Special Requirements For Hollow Composite Decking

If our standard size or color do not perfectly match your needs, we also offer custom service.

Resources on China Hollow Composite Decking

What Our Client Says

Our testimonials reveal how we have assisted our clients in accomplishing their ideas and the satisfaction they have derived from working with us.

Kenneth Li

Installed hollow composite decking on my lakeside cabin balcony last month – what a breeze! The planks were 40% lighter than solid alternatives, so my teenage son and I could handle them without professional help. The hidden clip system saved us 2 days of labor. Even after heavy rains, no warping or slippery surfaces. Perfect for DIYers on a budget!

Kellie S. Germany

As a property manager, I chose hollow composite decking for our 1,200 sq.ft apartment courtyard. The air-pocket design cut material costs by 35% compared to solid boards, yet it still handles foot traffic from 50+ daily residents. Three years in, zero splinters or fading – maintenance crews love hosing it down in minutes!

Donald M. Fiore

Game-changer for our Arizona backyard! The hollow channels keep the deck surface 15°F cooler than solid composites during summer. Our dog finally stopped burning his paws, and the kids play outside all day. Bonus: the hollow structure reduced echo when we added outdoor speakers!

Matthew Anderson

Switched from tropical hardwood to hollow composite decking for our eco-lodge walkways. The reduced material usage (30% less plastic/wood fibers) aligned with our sustainability goals, and guests rave about the realistic woodgrain texture. Passed monsoon season without mold – even in 90% humidity!

Common Questions Aabout Durable WPC Decking

Hollow composite decking is a lightweight, durable alternative to solid wood or traditional composite boards. Its hollow-channel design reduces weight while maintaining strength, making it ideal for DIY projects and elevated installations.

Hollow decking uses internal air gaps to lower weight and material costs, while solid composite decking is denser and heavier. Hollow boards are 30-40% lighter but still meet ASTM load-bearing standards for residential use.

No. The hollow structure allows for better thermal expansion/contraction management, reducing warping risk even in extreme temperatures (-30°C to 60°C). Proper 3-5mm gap spacing during installation is critical.

Hollow composite decking has a live load capacity of 300-400 lbs/sq.ft, suitable for patio furniture and grills. However, consult an engineer for hot tubs or heavy structures, as additional substructure support may be needed.

Use a soft brush and mild detergent. Avoid pressure washers above 1,500 PSI, as high-pressure water can force debris into hollow channels. Rinse thoroughly to prevent mold in humid climates.

Absolutely. The lightweight design (2.2-2.8 kg/m²) simplifies handling. Use corrosion-resistant stainless steel clips/screws, and follow the brand’s gap spacing guidelines for drainage/ventilation.

Reputable brands provide 15-25 year warranties covering fading, staining, and structural defects. Warranties often require professional installation and annual cleaning.

Related products

WPC Fencing

WPC Decking

WPC Cladding

The Best Choice For Durable WPC Decking