Showing all 2 results

PW-140S25 – Solid Traditional WPC Decking

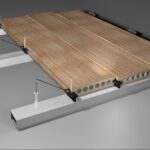

The PW-140S25 is a solid traditional WPC decking designed for durability and strength. Its solid core construction ensures superior load-bearing capacity, making it perfect for terraces, patios, and high-traffic areas. Enjoy the natural look of wood with minimal maintenance and eco-friendly benefits.

PWC-138S23 – Solid Co-extruded WPC Decking

PWC-138S23 is a solid co-extruded WPC decking by Plastory, designed for exceptional durability and strength. With a profile width of 138mm and thickness of 23mm, this decking is perfect for high-traffic areas and demanding outdoor applications. Its solid core construction provides superior load-bearing capacity, while the co-extruded protective layer offers excellent resistance to moisture, weather, and insects.

Solid WPC Decking: High-Density & Long-Lasting Outdoor Flooring

Solid WPC decking combines exceptional durability with a dense, non-hollow structure, making it perfect for high-traffic residential and commercial spaces. Engineered with premium wood-plastic composite (WPC) materials, it resists warping, moisture, mold, and heavy footfall while maintaining a natural wood-like appearance. Its slip-resistant surface and UV-stable formula ensure year-round safety and color retention, even in harsh weather. Ideal for pool decks, boardwalks, and outdoor hospitality venues, this low-maintenance decking requires no sanding or staining. Certified by FSC and GREENGUARD, it meets rigorous sustainability and indoor air quality standards. Choose solid WPC decking for unmatched strength and hassle-free longevity.

Solid Traditional WPC Decking Vs Solid Co-extruded WPC Decking

| Feature | Solid Traditional WPC Decking | Solid Co-extruded WPC Decking |

|---|---|---|

| Structure | Single-layer homogeneous composite material. | Dual-layer structure: dense core + protective outer shell. |

| Surface Finish | Uniform texture; may fade or scratch over time. | Enhanced UV-resistant top layer; resists fading/scratches. |

| Durability | High strength but prone to surface wear in harsh weather. | Superior weather resistance; outer shell shields the core. |

| Color Retention | Moderate; may require periodic sealing. | Excellent; co-extruded layer locks in color long-term. |

| Slip Resistance | Textured surface, but less resistant to algae/mold growth. | Anti-slip surface with mold-inhibiting properties. |

| Maintenance | Low maintenance but may need occasional cleaning/sealing. | Virtually maintenance-free; easy to clean with water. |

| Cost | Budget-friendly; lower production complexity. | Higher initial cost due to advanced manufacturing process. |

| Ideal Use Cases | Residential decks, low-traffic patios, budget projects. | High-traffic areas (pool decks, commercial spaces), harsh climates. |

| Eco-Friendliness | Recyclable, contains recycled wood/plastic. | Same eco-benefits, but longer lifespan reduces waste. |

Performance Characteristics And Practical Applications of Durable WPC Decking

Our product is the perfect solution for any location in need of flooring.

Durable WPC Decking Idea for Graden

Durable WPC Decking for Motor Home

Durable Decking for Outdoor Balcony

WPC Decking for Riverside Corridor

Durable Decking for Swimming Pool

Durable WPC Decking idea for Yacht

Why Choose Us

Are looking for high-quality and cost-effective WPC decking? our products maybe the best choice for durable WPC decking

Mature and great supply chain system

With China's biggest composite production base and full supply chain support, we deliver fast customization of materials while maintaining cost efficiency. Our complete industrial setup allows flexible WPC manufacturing tailored to your project needs.

More Tech accumulation and R&D

With more than 12 years of material engineering expertise, we dedicate not less than 6% of annual revenue to R&D. Our in-house lab develops 5-8 new composite formulas yearly, adapting technologies to meet evolving industry specifications.

Efficient customer service team

Our CS team operates on 2-hour response SLA with ERP-tracked workflows. From project scoping on Monday to Friday FOB shipments, we maintain 97% on-time delivery via Milestone Mapping system, backed by 48-month extended support including root-cause analysis reports.

Strict and Traceable quality control

Our production lines conduct 27 inspections per batch using XRF analyzers and thickness gauges. Certified to ISO 9001:2015 standards, we've maintained <0.3% defect rates since 2020 by implementing automotive-grade quality protocols.

Free and diverse samples to choose

If you don't know how to choose a product, we can send you free samples by mail. Shoot us your project specs – we'll fire back a custom sample kit with 30+ textures/colors, zero cost. So, No need to hesitate to contact us

Instant and professional quotation

Just tell us your demand or idea, we will recommend the best solution include WPC type, specs, and order size for you - our team cracks out a rock-bottom price and tightest delivery schedule in 30 mins flat. No more spreadsheet ping-pong for days.

Tell Us Special Requirements For Our Durable WPC Decking

If our standard size or color do not perfectly match your needs, we also offer custom service.

Resources on China durable WPC decking

What Our Client Says

Our testimonials reveal how we have assisted our clients in accomplishing their ideas and the satisfaction they have derived from working with us.

Thomas C. Kuhlman

As a serial home improver, I've used 5 decking materials. The wood-grain texture actually feels authentic, and the color hasn't faded after 18 months. Pro tip: their expansion gap calculator app saved my project!

Lucas R. Jackson

My climate guilt vanished when I found this decking. They plant 5 trees for every order through Arbor Day Foundation. The thermal stability is insane – left my metal chair out all summer, no ghost marks!

Cynthia K. Moore

After 3 harsh Minnesota winters, our WPC deck still looks brand new! Zero splinters for the kids, and I love that it's made from recycled milk jugs. The hidden clip system took us 2 hours to install – worth every penny!

Walter V. Shelton

Installed 2000+ sq.ft for a beachfront Airbnb. Saltwater? Hurricane winds? Bring it on. Guests keep asking if it's exotic hardwood – jokes on them, we saved 40% and passed HOA inspection in 1 shot!"

Common Questions Aabout Durable WPC Decking

Traditional WPC: Surface pitting from chloride penetration.

Co-extruded WPC: ASA capstock passes ASTM B117 salt spray test (2000 hours).

Regional Advisory: Mandatory for Great Lakes/Scandinavian projects.

Traditional WPC: Prone to surface algae growth (porosity 0.8-1.2%).

Co-extruded WPC: Non-porous capstock prevents spore penetration (0.02% water absorption rate).

Pro Tip: Choose co-extruded boards with Microban® antimicrobial coating for Florida/Caribbean installations.

Traditional WPC: Linear expansion coefficient of 0.7-1.2% (requires 8mm gap spacing).

Co-extruded WPC: Reduced expansion (0.3-0.5%) with patented locking systems allowing 5mm gaps.

Engineering Standard: ASTM D1037 high-temperature expansion testing.

Traditional WPC: Homogeneous composition (wood fiber and plastic blend throughout the entire profile).

Co-extruded WPC: Dual-layer armor structure – A protective capstock surface (ASA/PVC) fused to a reinforced WPC core.

Key Insight: Co-extruded surfaces improve UV resistance by 300% (tested per ASTM G154).

Traditional WPC: Maximum load capacity 350kg/m² (may show indentations).

Co-extruded WPC: HDPE-reinforced core withstands 500kg/m² (ideal for rooftop bars/commercial use).

Scenario Tip: Always choose co-extruded for outdoor kitchens or hot tub surrounds.

Traditional WPC: Visible fading (ΔE color difference >5) after 24 months.

Co-extruded WPC: ASA capstock ensures ΔE <2.5 (10-year fade warranty; QUV 3000hr = 5 years real-world testing).

Traditional WPC: Requires pre-drilling to prevent splitting (35-40N·m torque limit).

Co-extruded WPC: Self-tapping screws compatible + hidden fastener systems.

Time Saver: Co-extruded reduces installation time by 30%.

Related products

WPC Fencing

WPC Decking

WPC Cladding

Traditional WPC Decking